TEL. 03-5707-0104

1-28-1 Tamazutsumi, Setagaya-ku, Tokyo 158-8557, Japan

研究概要Introduction

Research subject

1.Research on next generation low losses ultra high thermal efficiency I. C. engine

In order to improve the thermal efficiency of next-generation gasoline, diesel and hydrogen engines,we are developing HEET's unique and special measurement technology that support to reduce energy loss and oil consumption mechanism in the combustion chamber, pistons, bearings, and other major components as well as to improve combustion process. We are promoting joint research with many companies and universities as one of the resarch hub station aiming for super high thermal efficiency.

2.Study on reducing mechanical friction loss of gasoline / diesel engine and elucidation of its mechanism

We are pursuing research to reduce the friction losses of the engine by applying following technologies:

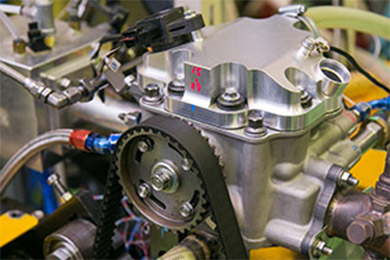

(1) Measurement of frictional force by floating liner method to measure the sliding friction force of the piston / piston ring during engine operation

(2) Unit test machine to measure the friction force / seizure condition of the plain bearing

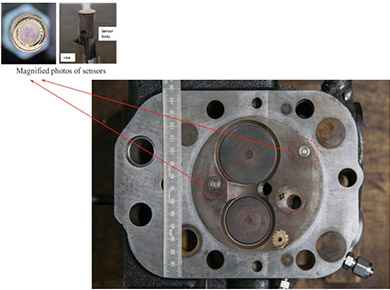

(3) Measurement of pressure distribution and fine clearance in the sliding portion of plain bearing by the proprietary thin film sensor

3.Study on cooling loss reduction of gasoline / diesel engine

We are conducting research to measure heat flux of the combustion chamber surface to coolant with high accurcy by applying the thin film heat flux sensor fabricated by our proprietary sputtering method and clarifying the characteristics of the cooling loss to reduce it..

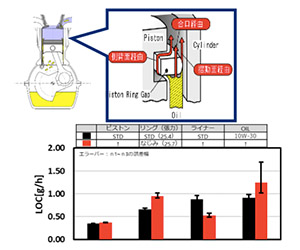

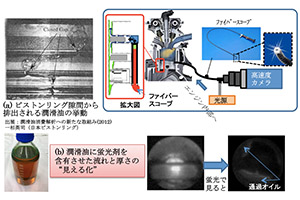

4.Reduction of oil consumption and study of its mechanism

Combining laser fluorescence method to visualize the oil film thickness and droplet scattering with measumrnt of oil consumption by the method of tracking additives in the oil, we are studying the mechanism of engine oil consumption and reducing the consumption.

5.Research on high thernal efficiency and low NOx hydrogen fueled engine

By combining newly developed combustion method ( Plume Ignition and Combustion Concept, PCC )with proprietary developed high-pressure hydrogen injector, we realized high thermal efficiency by reducing cooling loss which was a long-standing problem of hydrogen engine, and Near-zero NOx emissions at the same time. We will focus on futher improved thermal efficiency and zero NOx emissions.

Keyword

◆heat engine ◆fuel ◆lubricant oil ◆engine cooling

◆lubrication/tribology ◆hydrogen engine

Distinctive research facilities

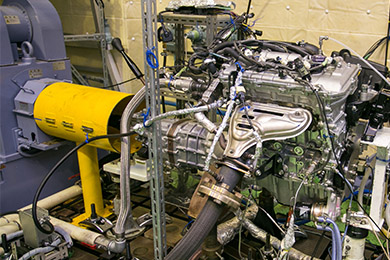

Friction force measurement system for single-cylinder engine based on floating liner method

Friction force measurement system based on floating liner method

Friction force measurement and seizure evaluation unit system for plain bearing

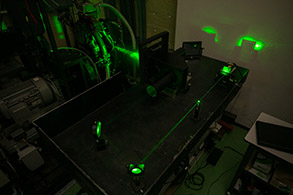

Optical hydrogen engine to visualize flame propagation and hydrogen jet

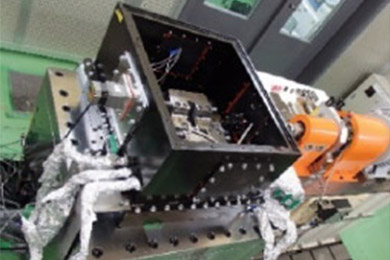

ALD (Atomic Layer Deposition)

System for fabricating thin insulation layer on thin film sensors

Sputtering equipment to fabricate thin electric insulating film on sensors for mearsuring oil film in engine sliding surface.

RF magnetron sputtering device for thin film heat flux sensor

Heat flux sensors attached to combustion chamber surfece of hydrogen engine

Introduction of research achievement

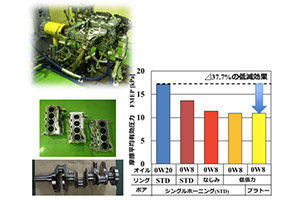

1.Study on reduction of friction loss

Improvement of each element such as use of crankshaft, cylinder bore, low viscosity lubricant with friction reduction realizes a large friction reduction effect.

We collaborate with other universities and companies to develop low friction parts and aim to improve fuel economy.

2.Direct measurement of frictional force by floating liner method

Initial evaluation of reduction of friction force of parts is carried out by using floating liner method applied to single cylinder gasoline engine. By applying the floating liner method using a doubly supported three-component force sensor, it is possible to conduct a highly accurate test.

Basic parts will be developed in cooperation with other universities and companies.

(One example of joint development: application of individual lubricant on piston skirt face (jointly with Meijo University)

3.Evaluation of trade-off between friction reduction effect and increase in engine oil consumption in engine component modification

In improving fuel economy targeted in next-generation gasoline engines by friction reduction, evaluation of lubricant oil consumption which is seemed to be trade-offs of friction reduction.

Our research facility and technology make it possible to measure both friction loss and lubricant oil consumption simultaneously.

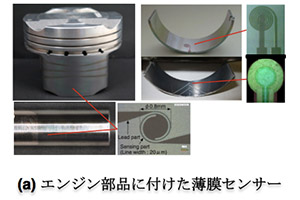

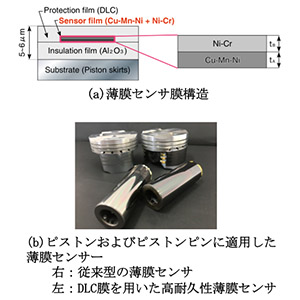

4.Real time monitoring of lubricating condition using thin film sensor

By using thin film sensors developed independently in this laboratory, we have grasped the oil film pressure, distance and temperature of the sliding portions of the constituting components, We are contributing to the improvement of the performance of internal combustion engines which are required to have high thermal efficiency.

5.Elucidation of lubricant oil consumption mechanism by laser induced fluorescence method

(LIF method)

6. Thin film pressure sensor (two layer membrane type sensor) for realizing ultra low friction engine

- (1)By depositing two kinds of sensor alloys on the surfece of the sensor to form two-layer film,it made possible to measure accurately the pressure of a portion with large deformation.

(Measurement error due to distortion is cancelled.) - (2)By applying DLC coating optimized for thin film pressure sensor, it made possible to have higher durability than before.

- (3)By combining the DLC film and the two-layered membrane type sensor, we successfully developed a thin film sensor corresponding to the requirement of the engine which becomes severely year by year.

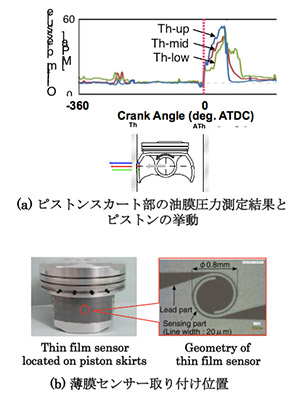

7.Measurement of oil film pressure of piston skirt by thin film pressure sensor

Since the two-layered membrane type thin film pressure sensor developed by HEET is not affected by the deformation of the skirt portion, and the DLC film protects the sensor against strong contact, the real time data acquisition of pressure in oil film is possible. In the future, we are going to measure oil film pressure in various points, in order to grasp all phenomena related to friction in the engine and also improve CAE analysis accuracy and realize ultra low friction engine.

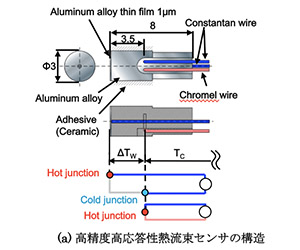

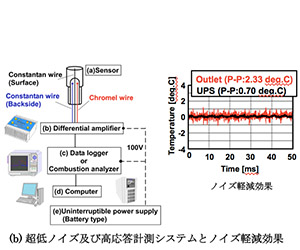

8.Development and application of high precision and responsiveness heat flux sensor

High responsiveness is realized by forming a thin film of 1 μm thickness on gas side of the combustion chamber using the sputtering method (PVD method), and high precision is realized by using the same materials as is used in combustion chamber for the sensor body.

In addition we have developed a responsivity evaluation device in which heat is irradiated to the sensor surface in a stepwise manner by laser and confirmed that the rise time of the sensor (63.2% value) is about 20 μs (= 50 kHz). Furthermore, we have developed to use ultra low noise and high response measurement system and realized significant noise reduction.

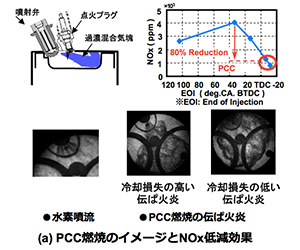

9.New combustion method of hydrogen engine PCC(Plume Ignition and Combustion Concept)

Burning an appropriately controlled rich air-fuel mixture by optimizing the shape of the hydrogen jet and the injection timing named PCC realized improvement of thermal efficiency and suppression of NOx emissions. We are conducting research to realize a next generation clean hydrogen engine that offers much more high thermal efficiency and low NOx emissions close to zero level by combining PCC combuston method with the high-pressure hydrogen injector developed at our university.

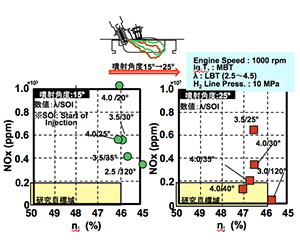

10.R&D of high thermal efficiency and near-zero emission hydrogen engine

By optimizing the shape of the hydrogen jet, directions of injected jet and the injection timing, we achieved dramatically low NOx emissions with high thermal efficiency which is appropriate to call hydrogen engine as near-zero emissions without CO2 emission.

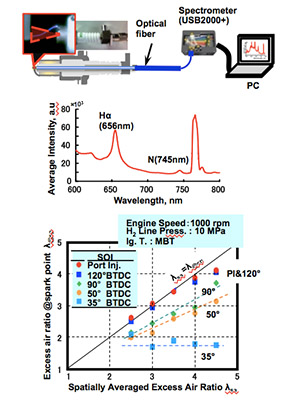

11.Measurement of local hydrogen concentration in combustion chamber of PCC combustion by spark discharge spectroscopy (SIBS method)

The local air-fuel ratio can be measured in the vicinity of the electrode of the spark plug by obtaining the spectrum emissions of hydrogen and nitrogen from the molecules at spark discharge. This method can measure quantitatively how the jet is concentrated around the spark plug and supported to realize high thermal efficiency near-zero emission hydrogen engine.

(Collaboration with Heat Power Eng. Lab., Okayama University)

12.Measurement of characteristics of heat flux in hydrogen engines

Characteristics of cooling loss in a hydrogen engine is measured by a heat flux sensor which is based on a thin film and developed at this laboratory. Following new findings are obtained from the research:

- (1) The heat flux on the leadind side of the injected hydrogen jet is significantly higher than the heat flux on the trailing side.

- (2) The heat flux on the leadind side and cooling loss increase under the retarded injection timing at which reduction in thermal efficiency can be realized, however the heat flux on the trailing side did not increased.

- (3) It implies that a key to reduce cooling loss in the direct injected hydrogen egine is haw to manage heat flux on the leadind side.